|

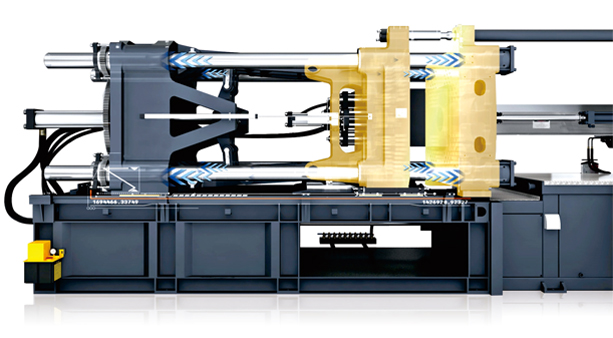

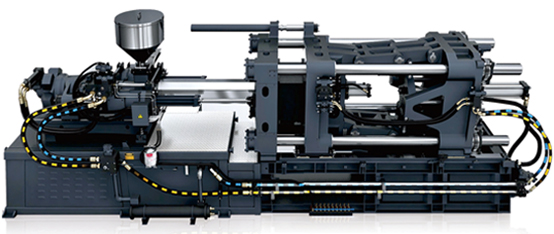

Clamping Unit

Strictly check the parallelism between fixed platen and movable platen, as well as the consistency of clamping force withstood by four tie bars.

|

|

Centering Bearing of Injection Unique injection tail platen, |

|

|

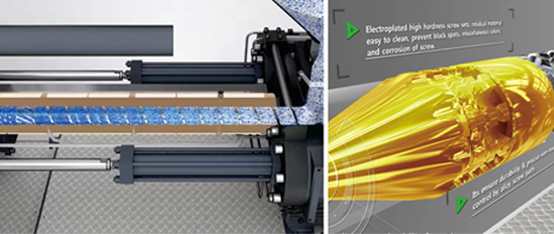

Screw Plasticizing Professional screw design, and melt density balance, ensure the physical character & weight of products. Screw compression ratio, L/D ratio, ensure material mixing & cutting completely, And minimized the difference between actual and setting temperature.

|

– OTHER SYSTEMS –

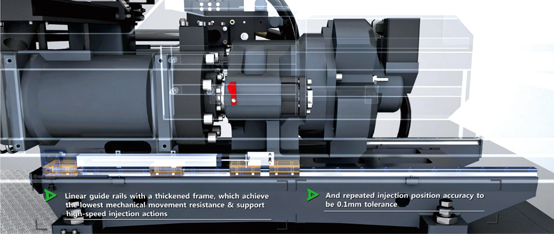

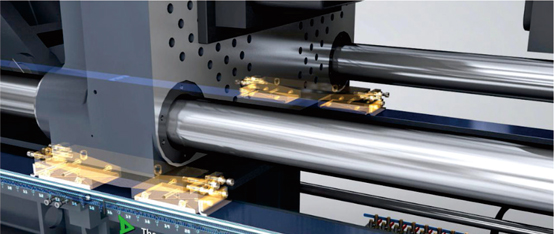

| Screw Tip Assembly | Linear Guide | |

|

|

|

| Electroplated high hardness screw sets, residual material easy to clean, prevent black spots, miscellaneous colors, and corrosion of screw. | Linear guide rails with a thickened frame, which achieve the lowest mechanical movement resistance & support high-speed injection actions. And repeated injection position accuracy to be 0.1mm tolerance. |

|

| Copper-Alloy Slides | Large-Diameter Oil Circuit | |

|

|

|

| The movable platen has copper-alloy double slides that reduce resistance when opening and closing the mold at high speed, ensuring long-lasting mechanical movement. | Adopt large-diameter oil circuit with low internal resistance control method to improve the response tempo and repeat accuracy of action. |

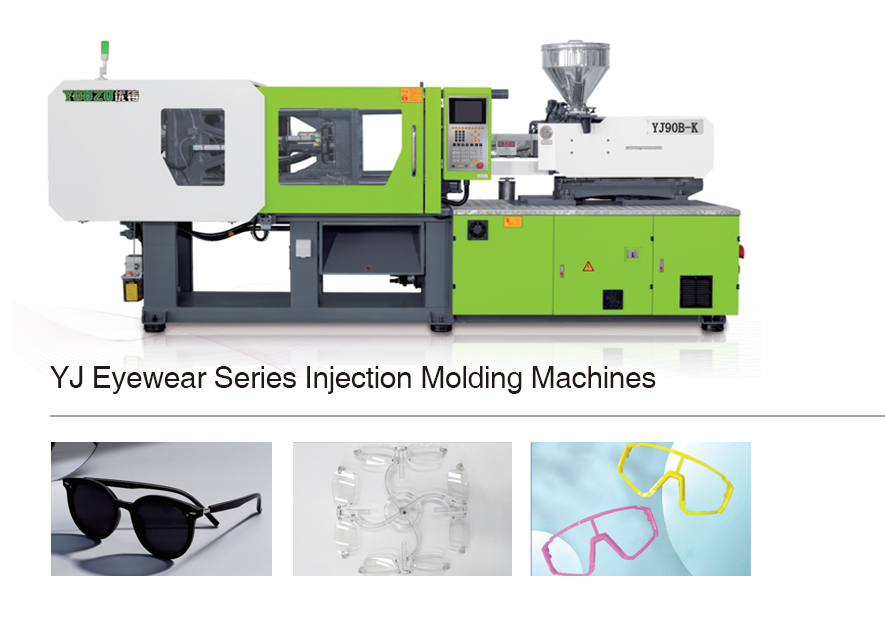

YJ Eyewear Injection Molding Machines Parameter

| Machine Type | Unit | YJ90S-K | YJ90B-K | GS100S-K | GS100B-K | YJ160S-K | YJ160B-K | ||||

| International Standard Model | 280/900 | 280/900 | 280/1000 | 280/1000 | 805/1600 | ||||||

| Injection System | |||||||||||

| Screw Diameter | mm | 28 | 31 | 28 | 31 | 28 | 31 | 28 | 31 | 40 | 40 |

| Screw L/D Ratio | L:D | 22:1 | 20:1 | 22:1 | 20:1 | 22:1 | 20:1 | 22:1 | 20:1 | 23:1 | 23:1 |

| Injection Volume | CC | 74 | 91 | 74 | 91 | 74 | 91 | 74 | 91 | 265 | 265 |

| Injection Weight (PC) | g | 79 | 97 | 79 | 97 | 79 | 97 | 79 | 97 | 284 | 284 |

| OZ | 2.8 | 3.4 | 2.8 | 3.4 | 2.8 | 3.4 | 2.8 | 3.4 | 9.9 | 9.9 | |

| Injection Speed | mm/s | 88 | 88 | 67 | 67 | 88 | 88 | 67 | 67 | 84 | 62 |

| Injection Rate | cm³ /sec | 54 | 66 | 41 | 51 | 54 | 66 | 41 | 51 | 106 | 78 |

| Injection Pressure | Mpa | 380 | 310 | 380 | 310 | 380 | 310 | 380 | 310 | 304 | 304 |

| Injection Stroke | mm | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 211 | 211 |

| Screw Speed | r/min | 230 | 230 | 175 | 175 | 230 | 230 | 175 | 175 | 240 | 175 |

| Clamping System | |||||||||||

| Clamping Force | kN | 900 | 900 | 1000 | 1000 | 1600 | 1600 | ||||

| Clamping Stroke | mm | 320 | 320 | 340 | 340 | 425 | 425 | ||||

| Max Platen Opening | mm | 680 | 680 | 720 | 720 | 925 | 925 | ||||

| Min-Max Mold Thickness | mm | 130-360 | 130-360 | 140-380 | 140-380 | 160-500 | 160-500 | ||||

| Dist. between Tiebars | mmxmm | 360×360 | 360×360 | 360×360 | 360×360 | 460×460 | 460×460 | ||||

| Platen Dimension | mmxmm | 550×550 | 550×550 | 550×550 | 550×550 | 670×670 | 670×670 | ||||

| Ejector Force | kN | 23 | 23 | 34 | 34 | 42 | 42 | ||||

| Ejector Stroke | mm | 80 | 80 | 100 | 100 | 140 | 140 | ||||

| Ejector Pin Quantity | pcs | 1 | 1 | 5 | 5 | 5 | 5 | ||||

| Power Unit | |||||||||||

| System Pressure | Mpa | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | ||||

| Oil Pump Motor | KW | 17 | 7.5 | 17 | 7.5 | 27 | 15 | ||||

| Oil Pump Motor | KW | 6.5 | 6.5 | 6.5 | 6.5 | 10.9 | 10.9 | ||||

| Temperature Control Zone | section | 5 | 5 | 5 | 5 | 5 | 5 | ||||

| General | |||||||||||

| Oil Tank Capacity | L | 160 | 160 | 175 | 175 | 230 | 230 | ||||

| Machine Weight | Tons | 3.1 | 3.1 | 3.8 | 3.8 | 4.7 | 4.7 | ||||

| (LxWxH) | mxmxm | 3.84×1.08×1.76 | 3.84×1.08×1.76 | 4.62×1.15×1.86 | 4.62×1.15×1.86 | 4.59×1.29×1.97 | 4.59×1.29×1.97 | ||||