|

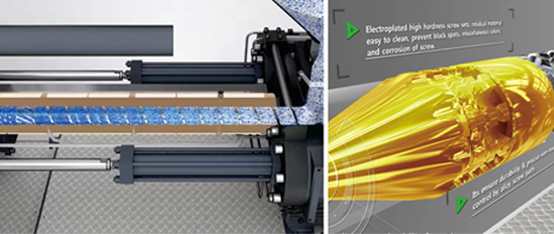

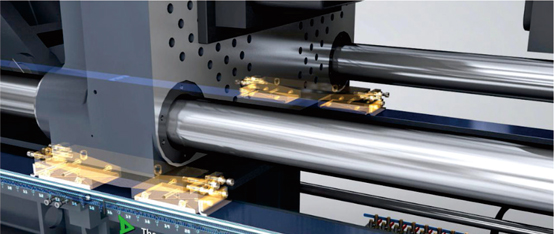

Hard and smooth screw assembly are special for MIM. The compression ratio, flow length ratio, three-section ratio, and other parameters are designed for the characteristics of raw materials. All of them are made from imported materials and conform to strict tolerance standards.

The screw assembly can stabilize the plasticizing temperature to achieve high-quality plasticizing and mixing, and are more wear-resistant and durable to provide high injection precision.

|

|

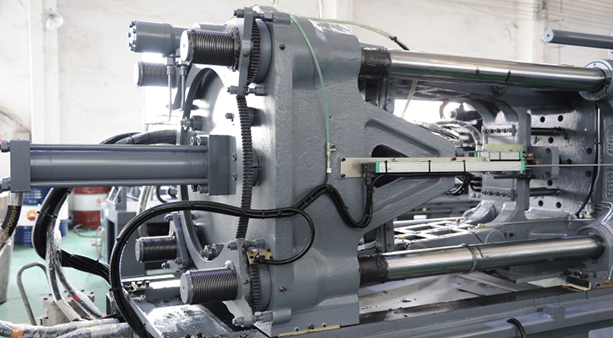

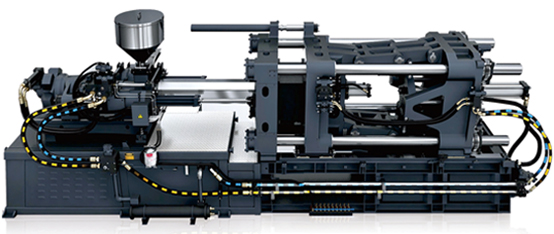

Upgrade mold adjustment structure and thicker platens contribute to high-pressure clamping without loosening and low deformation of the clamping unit. Strengthened toggles and cross plate of the clamping unit optimize the clamping curve, improve durability, and accelerate mold opening. |

|

|

The high-power servo drivers are matched with the high-torque servo motors and permanent magnets at the highest SH level. This power train is designed for low RPM and high torque, with sufficient overload capacity and consistent performance in reliability tests under adverse conditions.

|

|

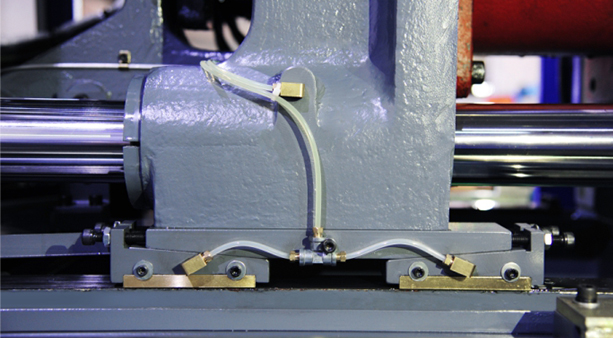

The movable platen has copper-alloy double slides that increase the force area and reduce the pressure of alloy plates, more long-lasting than using regular single slides. The slides have a good load-bearing support ratio for fast and heavy mold opening and closing, and also guarantees force uniformity in toggles and tie bars. |

|

– OTHER SYSTEMS –

| Screw Tip Assembly | Linear Guide | |

|

|

|

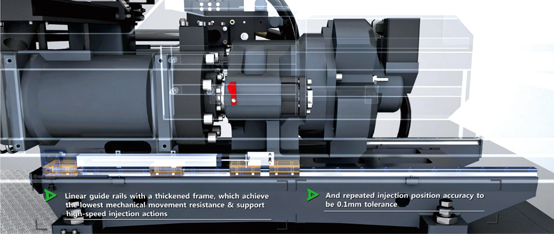

| Electroplated high hardness screw sets, residual material easy to clean, prevent black spots, miscellaneous colors, and corrosion of screw. | Linear guide rails with a thickened frame, which achieve the lowest mechanical movement resistance & support high-speed injection actions. And repeated injection position accuracy to be 0.1mm tolerance. |

|

| Copper-Alloy Slides | Large-Diameter Oil Circuit | |

|

|

|

| The movable platen has copper-alloy double slides that reduce resistance when opening and closing the mold at high speed, ensuring long-lasting mechanical movement. | Adopt large-diameter oil circuit with low internal resistance control method to improve the response tempo and repeat accuracy of action. |

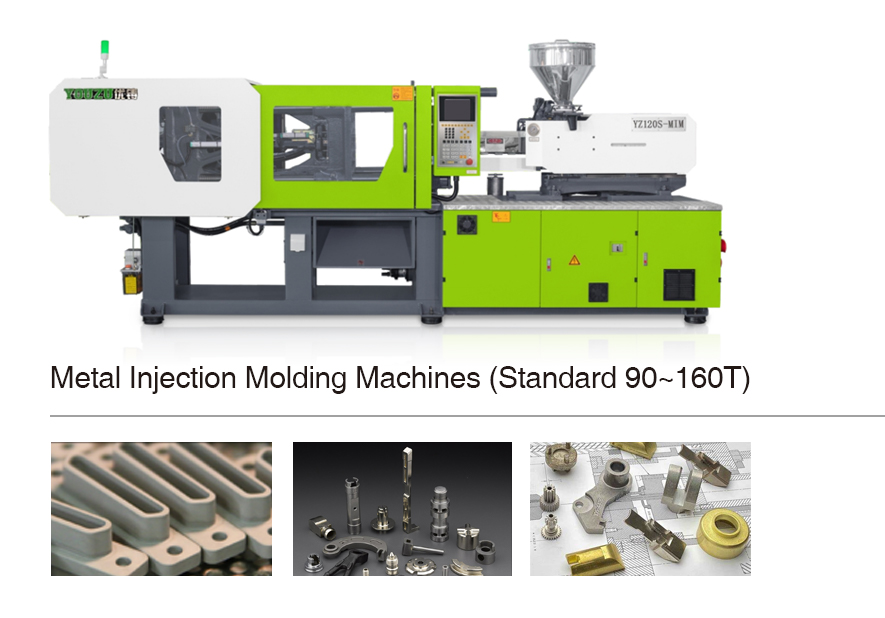

Metal Injection Molding Machines Parameter

| Model | YZ90S-MIM | Y120S-MIM | YZ160S-MIM | ||||

| International Standard Model | Unit | 194/900 | 228/900 | 228/1200 | 439/1600 | ||

| Injection Unit | |||||||

| Screw Diameter | mm | 22 | 26 | 26 | 28 | 31 | 36 |

| Screw L/D Ratio | L:D | 22:1 | 22:1 | 22:1 | 20.5:1 | 22:1 | 20.5:1 |

| Injection Volume | cm³ | 62 | 86 | 86 | 100 | 142 | 191 |

| Injection Weight | g | 326 | 456 | 456 | 528 | 752 | 1014 |

| oz | 11.4 | 15.9 | 15.9 | 18.5 | 26.3 | 35.5 | |

| Injection Pressure | Mpa | 316 | 257 | 257 | 221 | 273 | 203 |

| Injection Speed | mm/s | 171 | 151 | 188 | 188 | 156 | 156 |

| Injection Rate | cm³/s | 65 | 80 | 100 | 116 | 117 | 158 |

| Injection Stroke | mm | 162 | 162 | 162 | 162 | 188 | 188 |

| Screw Speed | rpm | 221 | 221 | 276 | 276 | 295 | 295 |

| Clamping System | Five Point Toggle | ||||||

| Clamping Force | KN | 900 | 1200 | 1600 | |||

| Clamping Stroke | mm | 320 | 360 | 425 | |||

| Max Platen Opening | mm | 680 | 810 | 925 | |||

| Min-Max Mold Thickness | mm | 130-360 | 145-450 | 160-500 | |||

| Dist. between Tiebars (Horizontal*Vertical) | mm×mm | 360×360 | 410×410 | 460×460 | |||

| Platen Dimension (Horizontal*Vertical) | mm×mm | 550×550 | 600×600 | 670×670 | |||

| Diameter of Mold Locating Hole | mm | ∅100H8 | ∅125H8 | ∅125H8 | |||

| Ejector Force | KN | 23 | 34 | 42 | |||

| Ejector Stroke | mm | 80 | 120 | 140 | |||

| Ejector Pin Quantity | pcs | 1 | 5 | 5 | |||

| Power Unit | |||||||

| System Pressure | Mpa | 17.5 | 17.5 | 17.5 | |||

| Oil Pump Motor | KW | 17 | 20 | 27 | |||

| Heating Power | KW | 5.5 | 6.5 | 6.5 | 9.8 | ||

| Temperature Control | section | 5 | 5 | 5 | |||

| General | |||||||

| Oil Tank Capacity | L | 160 | 185 | 230 | |||

| Machine Weight | Tons | 3.1 | 3.7 | 4.6 | |||

| Overall Dimension(LxWxH) | mxmxm | 3.84×1.08×1.76 | 4.3×1.16×1.85 | 4.6×1.29×1.97 | |||