|

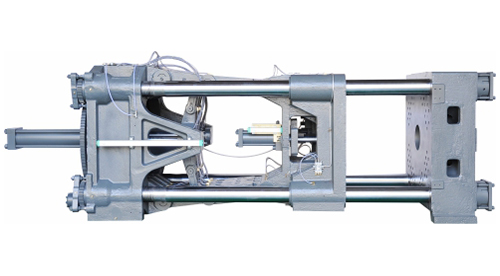

CLAMPING UNIT

A rigid and robust mold clamping structure enhances durability under operating conditions of high speed and high pressure.

|

|

SCREWS Specifically designed plasticizing screws achieve even color mixing and effective plasticizing. |

|

|

NOZZLE STRUCTURE Specifically designed filter with strong strength ensures the hot runner of the mold is not blocked.

|

– OTHER SYSTEMS –

| Nozzle Cover | Back Pressure | |

|

|

|

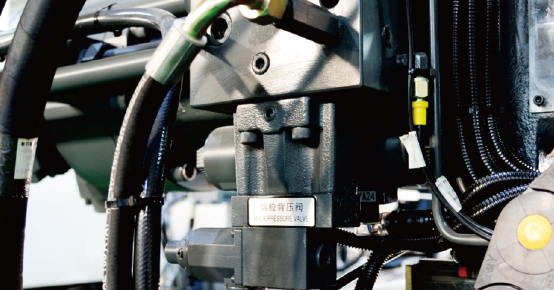

| A nozzle cover is equipped to protect workers from injuries caused by accidental hot melt splashes. | Digital control of proportional back pressure and individual oil circuit allow convenient, quick, and accurate adjustment of the plasticizing back pressure for better control of the density of melt, simplifying technical data statistics and archiving. | |

| Linear Guides | Integrated Advantages | |

|

|

|

| The injection table adopts linear ball rails and an integral support with higher rigidity, providing minimal resistance of smooth mechanical motion to achieve high precision and durability. | Integrate the design advantages of machinery, oil circuits, and electric control for fast mold opening and clamping. The stable stop position of mold opening minimizes impact, and mold clamping is equipped with sensitive low-voltage protection. | |

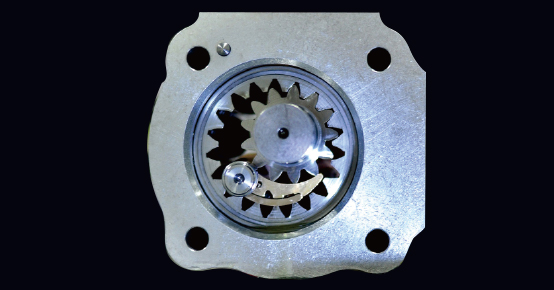

| Rigorous Testing | Internal Gear Pump | |

|

|

|

| Melt density and injection precision are designed based on rigorous analysis and testing, ensuring the weight repeatability of plastic products. | Equipped with an imported internal gear pump, this servo pump provides stable output pressure and low internal leakage so that it can withstand a maximum continuous working pressure of up to 25MPa, making it highly advantageous for precision injection, low-speed and high-pressure molding, and other applications. | |

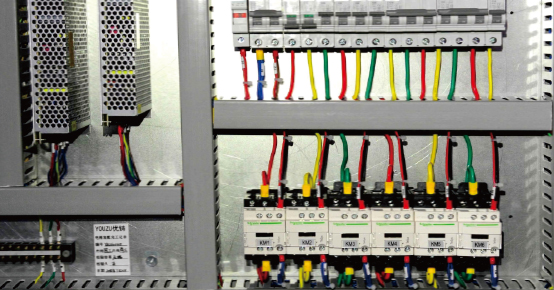

| Electrical Components | 100% Inspection | |

|

|

|

| High-quality imported electrical components (Schneider/TE) are combined with interference-resistant circuits to ensure a long lifespan even with frequent switching and connection. | 100% inspection tests the clamping force and parallelism, which shows our confidence in the machining precision and assemble quality of the mechanical parts. Adequate clamping force reduces tension on tie bars and ensures uniform force distribution. |

GS Drip Tape Emitter Parameter

| Model | Unit | GS280 | GS338 | ||

| International Standard | 1414/280 | 1322/280 | 1992/338 | 1992/338 | |

| Injection Table Model | D1410( Single Cylinder) | S1322(Double Cylinders) | D2100(Single Cylinder) | S1992(Double Cylinders) | |

| Screw Diameter | mm | 60 | 60 | 67 | 67 |

| Screw L/D Ratio | \ | 22 | 21.3 | 22 | 22 |

| Injection Pressure | Mpa | 175 | 169 | 180 | 175 |

| Theoretical Injection Weight (PS) | g | 733 | 710 | 1058 | 1033 |

| oz | 25.7 | 24.8 | 37.0 | 36.1 | |

| Injection Speed | mm/s | 205 | 210 | 175 | 180 |

| Injection Rate | cm³/sec | 579 | 593 | 617 | 634 |

| Theoretical Injection Volume | cm³ | 806 | 780 | 1163 | 1135 |

| Injection Stroke | mm | 285 | 276 | 330 | 322 |

| Screw Rotation Rate | r/mim | 250 | 250 | 250 | 250 |

| Clamping System Category | |||||

| Clamping Force | tons | 280 | 280 | 338 | 338 |

| Clamping Stroke | mm | 580 | 580 | 660 | 660 |

| Max Platen opening | mm | 1180 | 1180 | 1360 | 1360 |

| Min-Max Mould Thickness | mm | 220-600 | 220-600 | 250-700 | 250-700 |

| Dist. between Tiebars (Horizontal*Vertical) | mmxmm | 610×610 | 610×610 | 680×680 | 680×680 |

| Platen Dimension (Horizontal*Vertical) | mmxmm | 890×890 | 890×890 | 975×975 | 975×975 |

| Diameter of Mold Locating Hole | mm | ∅160H8 | ∅160H8 | ∅160H8 | ∅160H8 |

| Ejector Force | tons | 11.1 | 11.1 | 11.1 | 11.1 |

| Ejector Stroke | mm | 180 | 180 | 200 | 200 |

| Ejector Pin Quantity | pcs | 13 | 13 | 13 | 13 |

| Power/Electric Heating | |||||

| System Pressure | Mpa | 17.5 | 17.5 | 17.5 | 17.5 |

| Oil Pump Motor | kW | 65+20 | 65+20 | 65+27 | 65+27 |

| Heating Power | kW | 18.3 | 17.7 | 20.0 | 20.9 |

| Temperature Control Zone | section | 5 | 5 | 5 | 5 |

| Other | |||||

| Oil Tank Capacity | L | 550 | 550 | 680 | 680 |

| Machine Weight | Tons | 10 | 10 | 12.3 | 12.3 |

| Overall Dimension(LxWxH) | mxmxm | 6.95×1.48×2.15 | 6.95×1.48×2.15 | 7.79×1.6×2.21 | 7.79×1.6×2.21 |

| Quantity of Mold Cavities | 448 | 448 | 512 | 512 | |