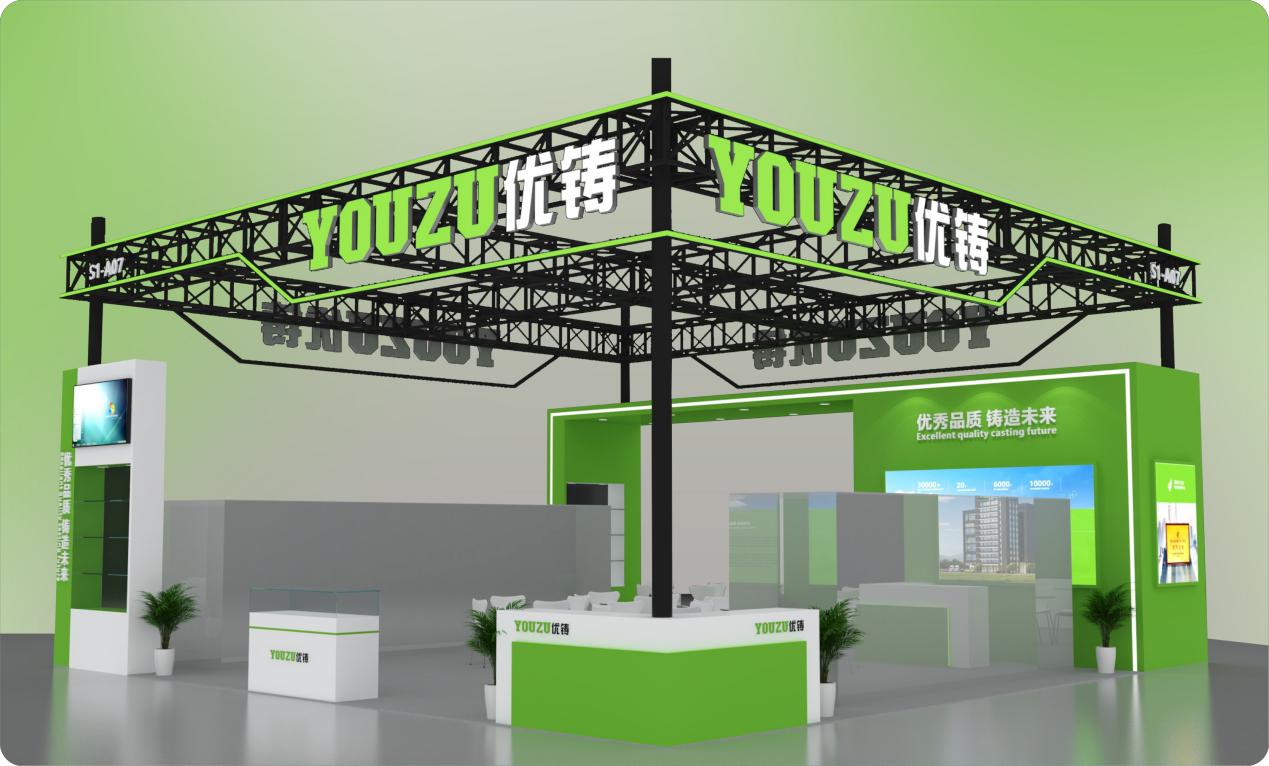

From September 15-17, YOUZU will participate in the 6th China (Chongqing) International Plastics Industry Exhibition (CPLAS 2023), which will be held at Chongqing International Expo Center, with booth No. A07 in Hall S1.

Exhibition Introduction

CPLAS 2023

CPLAS 2023, the highest specification, fastest-growing, and largest potential professional exhibition platform for the plastics industry in western China, will be held under the theme of “Innovation, Intelligence, Green, Recyclability”.

Organized by China Plastics Machinery Industry Association, the event spans 23,000 square meters and hosts over 500 exhibitors. Thousands of visitors from across China are expected to attend, seeking new opportunities and advancements in the plastics industry.

Chongqing

Chongqing, the only municipality in central and western China, stands as the premier laptop production base and holds a position of significance in China’s automobile production sector, ranking in the top ten national producers of plastic products from January-October 2022.

For a decade, YOUZU has been committed to R&D and innovation with the aim of the green development and recycling of the plastics industry.

At this exhibition, YOUZU will show its excellent technology and solutions, which are a must-see for you.

Exhibited Machines

The updated third-generation standard series, YZ160S-IIIS, and the electrical plasticizing series, DR200, will be present with comprehensive consulting services and advanced intelligent injection molding solutions. You will experience professional and high-tech services provided by YOUZU at the exhibition.

01. YZ160S-IIIS—the standard series injection molding machines

Machine Introduction

◆Strengthened three molding platens with the center-force design and finite element force analysis, optimize the mechanical curve of the clamping toggles, resulting in faster and more accurate opening and closing of the mold.

◆Strictly check the parallelism between fixed platen and movable platen, as well as the consistency of clamping force withstood by four tie bars.

◆The moving platen has copper-alloy double slides that reduce resistance when opening and closing the mold at high speed, ensuring long-lasting mechanical movement

◆Adopt large diameter oil circuit with low internal resistance control method to improve the response tempo and repeat accuracy of action

Applications

Home appliances / 3c electronic accessories / cell phone accessories/ computer parts/ daily necessities / food packaging / daily chemical packaging / switch and lighting / optical lens / auto parts / medical supplies

02. DR200—the electrical plasticizing series

Machine Introduction

◆Energy saving: The plasticizing screw is directly driven by a servo motor through a reduction gearbox, which can save energy by 15-25% compared with the hydraulic system, avoiding double loss of oil pump and volumetric efficiency of oil motor, as well as the pressure loss of hydraulic hoses.

◆Synchronization: The plasticizing process is synchronized with mold opening, shortening the cycle of products molding. (Should be supported by needle valve hot runner mold)

◆Responsive: Directly driven by a servo motor, the plasticizing process has low inertia and fast response.

◆Stability: Stable screw speed and precise plasticizing volume without hydraulic pulse effects.

◆Eco-friendly: efficient electrical plasticizing, low energy cost, low cooling water consumption, low noise level

Applications

Auto parts / home appliances / medical supplies / daily necessities

We believe that CPLAS 2023 will bring new opportunities and development for the industry, and sincerely invite you to attend the exhibition together to promote the injection molding machine industry to a higher level!