|

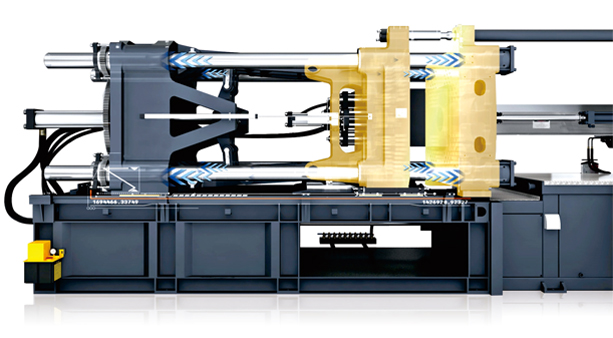

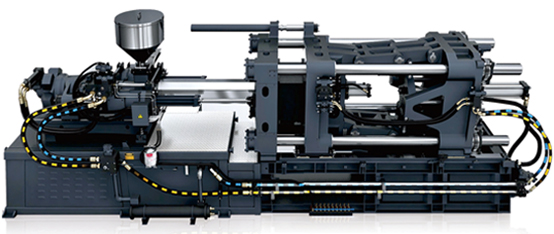

Clamping Unit

Strictly check the parallelism between fixed platen and movable platen, as well as the consistency of clamping force withstood by four tie bars.

|

|

Centering Bearing of Injection Unique injection tail platen, |

|

|

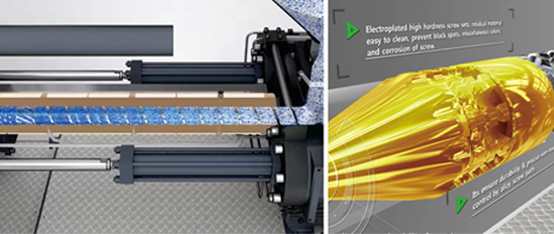

Screw Plasticizing Professional screw design, and melt density balance, ensure the physical character & weight of products. Screw compression ratio, L/D ratio, ensure material mixing & cutting completely, And minimized the difference between actual and setting temperature.

|

– OTHER SYSTEMS –

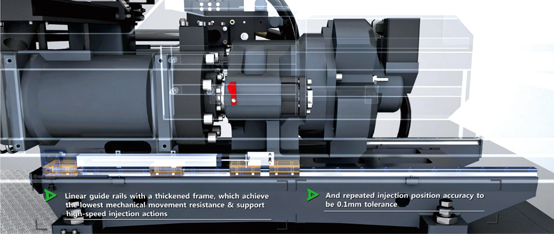

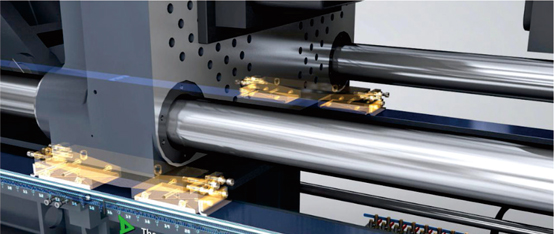

| Screw Tip Assembly | Linear Guide | |

|

|

|

| With electroplated high hardness screw sets, residual materials are easy to clean to prevent black spots, miscellaneous colors, and corrosion of screw. | Linear guide rails with a thickened frame, which achieve the lowest mechanical movement resistance & support high-speed injection actions. And repeated injection position accuracy to be 0.1mm tolerance. |

|

| Copper-Alloy Slides | Large-Diameter Oil Circuit | |

|

|

|

| The movable platen has copper-alloy double slides that reduce resistance when opening and closing the mold at high speed, ensuring long-lasting mechanical movement. | Adopt large-diameter oil circuit with low internal resistance control method to improve the response tempo and repeat accuracy of action. |

3S Series Servo Motor Machines Parameter

| Discription | UNIT | YZ90S-ⅢS | YZ120S-ⅢS | YZ160S-ⅢS | YZ200S-ⅢS | YZ260S-ⅢS | ||||||||||||

| International Standard Model |

296/900 | 441/1200 | 660/1600 | 912/2000 | 1322/2600 | |||||||||||||

| Injection Unit | ||||||||||||||||||

| Screw Type | U | A | B | C | U | A | B | C | A | B | C | A | B | C | A | B | C | |

| Screw Diameter | mm | 28 | 31 | 36 | 42 | 31 | 36 | 42 | 46 | 42 | 46 | 52 | 46 | 52 | 60 | 52 | 60 | 67 |

| Screw L/D Ratio | L:D | 20.5 | 23.2 | 20.0 | 17.1 | 20 | 23.4 | 20.1 | 18.3 | 22 | 20.1 | 17.8 | 23.3 | 20.6 | 17.8 | 24.6 | 21.3 | 19.1 |

| Injection Volume | cc | 100 | 122 | 165 | 224 | 142 | 191 | 260 | 312 | 292 | 350 | 448 | 397 | 507 | 675 | 586 | 780 | 973 |

| Injection Weight | g | 91 | 111 | 150 | 204 | 129 | 174 | 237 | 284 | 266 | 319 | 407 | 361 | 461 | 614 | 533 | 709 | 884 |

| oz | 3.2 | 3.9 | 5.2 | 7.1 | 4.5 | 6.1 | 8.3 | 9.9 | 9.3 | 11.2 | 14.2 | 12.6 | 16.1 | 21.5 | 18.6 | 24.8 | 30.9 | |

| Injection Speed | mm/s | 112 | 110 | 103 | 106 | 107 | ||||||||||||

| Injection Rate | cm³/sec | 69 | 85 | 114 | 155 | 83 | 111 | 152 | 182 | 142 | 171 | 218 | 176 | 225 | 300 | 228 | 303 | 378 |

| Injection Pressure | Mpa | 297 | 242 | 180 | 132 | 310 | 230 | 169 | 141 | 226 | 188 | 147 | 230 | 180 | 135 | 226 | 169 | 136 |

| Injection Stroke | mm | 162 | 188 | 211 | 239 | 276 | ||||||||||||

| Screw Speed | rpm | 230 | 230 | 224 | 211 | 201 | ||||||||||||

| Clamping System | ||||||||||||||||||

| Clamping Force | kN | 900 | 1200 | 1600 | 2000 | 2600 | ||||||||||||

| Clamping Stroke | mm | 320 | 360 | 425 | 480 | 540 | ||||||||||||

| Max Opening of the Mold | mm | 680 | 810 | 925 | 1030 | 1140 | ||||||||||||

| Min-Max Mold Thickness | mm | 130-360 | 145-450 | 160-500 | 180-550 | 195-600 | ||||||||||||

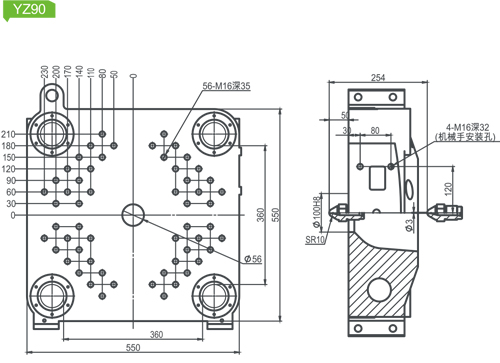

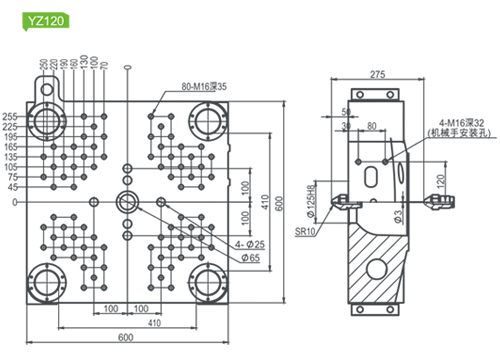

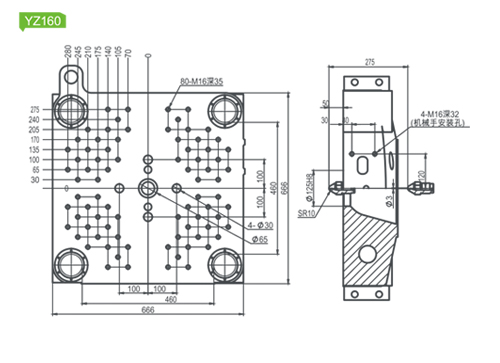

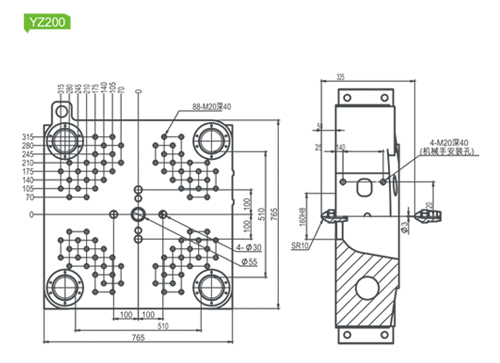

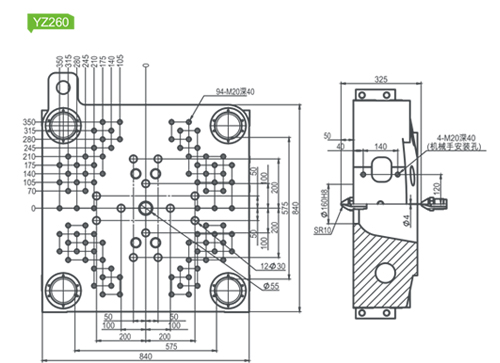

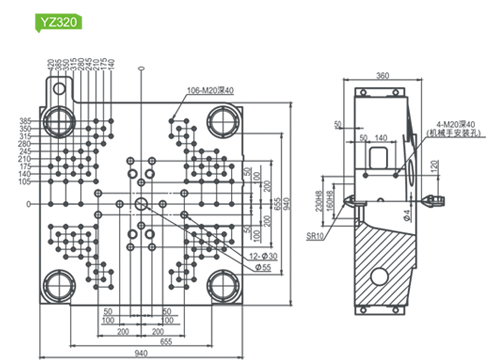

| Internal Range of Four Tie Bars |

mm | 360×360 | 410×410 | 460×460 | 530×510 | 610×575 | ||||||||||||

| Mold Dimension | mm | 550×550 | 600×600 | 686×686 | 785×765 | 875×840 | ||||||||||||

| Diameter of Mold Positioning Hole | mm | Φ100H8 | Φ125H8 | Φ125H8 | Φ160H8 | Φ160H8 | ||||||||||||

| Ejector Force | kN | 23 | 34 | 42 | 67 | 77 | ||||||||||||

| Ejector Stroke | mm | 80 | 120 | 140 | 150 | 180 | ||||||||||||

| Ejector Pin Quantity | pcs | 1 | 5 | 5 | 5 | 13 | ||||||||||||

| Power unit | ||||||||||||||||||

| System Pressure | Mpa | 14.5 | 17.5 | 17.5 | 17.5 | 17.5 | ||||||||||||

| Oil Pump Motor | kW | 17 | 20 | 27 | 32 | 37 | ||||||||||||

| Heating Power | kW | 6.5 | 9.8 | 10.9 | 14.0 | 17.7 | ||||||||||||

| Temperature Control Zone | segment | 5 | 5 | 5 | 5 | 5 | ||||||||||||

| General | ||||||||||||||||||

| Oil Tank Capacity | L | 160 | 170 | 210 | 250 | 370 | ||||||||||||

| Machine Weight | Tons | 3.1 | 3.8 | 4.7 | 6.2 | 8.5 | ||||||||||||

| Overall Dimension (LxWxH) |

mxmxm | 3.84×1.08×1.76 | 4.3×1.16×1.85 | 4.59×1.29×1.97 | 5.19×1.36×1.94 | 6.13×1.49×2.06 | ||||||||||||